Starting a piston engine aircraft is not always straight forward. There are several considerations to ensure it gets done safely and efficiently.

Introduction

Starting aircraft piston engines can be a daunting task for student pilots. There are many things that need to be considered in order to start the engine safely and efficiently. In this blog post, we will discuss the proper way to start a piston engine aircraft. We will cover all of the steps that need to be taken, from checking the fuel level to priming the aircraft engine. If you are a student pilot working on your pilot certificate, make sure you read this post, as starting most aircraft engines will take knowledge and experience.

What does an engine need1 to start?

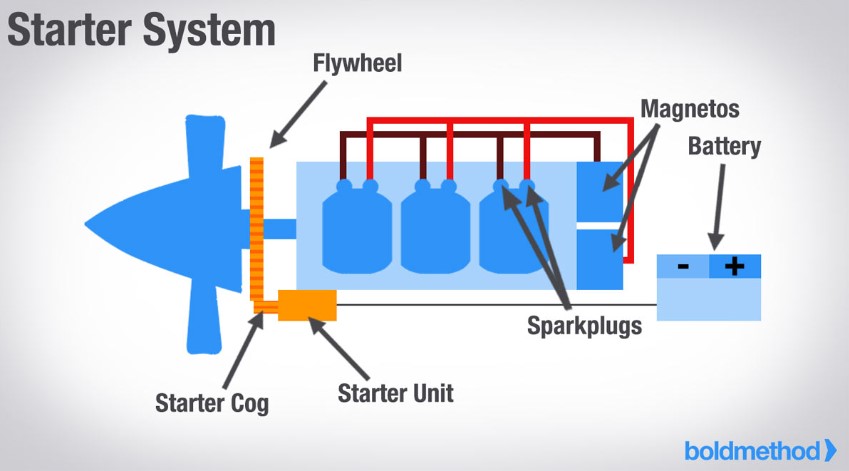

There are four things an engine needs to start – air, fuel, ignition and compression.

- Fuel is controlled using the fuel selectors, mixture control and any booster or priming systems

- Air (and also fuel) is regulated by the throttle

- Ignition is controlled via the magnetos

- Compression is controlled by cranking the engine, either using an electronic or pneumatic starter, or by hand swinging the prop (prop starting is very dangerous and should be avoided unless absolutely needed – many airmen have been killed hand swinging props).

Pre-flight checks

The first step in starting a piston engine aircraft is to of course ensure you have completed your pre-flight inspection including checking the fuel level. You obviously need to make sure that there is enough fuel in the tank to power the engine for your flight. In the RAAF, I was taught to always do the fuel and the oil level check first, and then once I had verified the fuel and oil level, I moved onto the walkaround. Make sure your aircraft is oriented safely, so you aren’t going to direct dangerous (or irritating) propwash

The second step is to set your aircraft up the correct way for flight, and do your ‘nesting’ procedure. This means configuring the aircraft the way you like, placing checklists, kneepads and other tools appropriately. After your ‘nesting’ or set up, you should methodically go through the cockpit completing your ‘flight deck preparation procedure’ and ensuring all switches are set in the correct position for engine start in accordance with your flight manual and company SOPs. The engine will definitely not start if you haven’t got the fuel cock selected to ON! (Ask me how I know…)

The third step is to go through your Before engine start checklist. Be wary, you may need permission to start engines from Air Traffic Control (thankfully an airways clearance usually always constitutes permission to start engines). This is especially true for busy airports or if there is active parachute operations occurring.

“Achieving the proper balance is crucial because it will burn the fuel into energy; however, producing exact measurements is difficult. The pilot or mechanic must consider pressure, temperature, and moisture while measuring exactly how much fuel is needed for the mixture.”

aviationoiloutlet.com/blog/when-to-prime-a-piston-engine 2

Starting a piston engine aircraft

OK – with this out of the way we get to the actual starting of the engines. Each engine is slightly different, and you should always follow the technical specifications listed in the pilots operating handbook, your company standard operating procedures and what you have been taught by a qualified flight instructor or line checker. But, as an overview;

- Prime Engine2

- Set mixture as required (for carburetted aircraft engines we typically select full rich, however for fuel injected systems we select full lean and then as the engine starts we smoothly push it into the full rich position)

- ‘Crack’ the throttle open ~1cm

- Switch Magnetos to ‘on’

- Turn ignition key (or press ‘START’ button)

- When engine starts positively retard throttle to below 1000 RPM and select mixture as appropriate (ground lean). For fuel injection systems/ starts, you obviously have to quickly select full rich as it starts or the engine will idle cut out.

Priming the engine

This means adding jet fuel directly into the cylinders of the engine in order to get it started. There are several ways to do this, but the most common methods are by using a fuel pump (running it with mixture in until fuel pressure rise is seen), using a primer piston plunger (often next to the carburettor heat control), for some older warbirds using the hand ‘wobble’ pump, or for ultralights potentially using a primer bulb on the engine directly. The primer bulb is located on top of the carburetor and it looks like a small rubber ball. You need to squeeze the primer bulb until it is hard, then release it (sometimes several times). This will add fuel into the air cooled cylinders and help start the engine.

Starting the engine

The trick to getting a quick start3 is having air and fuel mixed together in the right ratio so the mixture ignites easily. The optimum air / fuel ratio is around 16:1, and is known as the Stoichiometric Ratio which is the mixture where no excess fuel or oxygen is left after combustion. This is good in theory, but practically we cant actually set this ratio.

Therefore, the ideal technique is to prime the engine carburetor/induction manifold/cylinders with just a little fuel, and starting with the throttle almost fully closed, crank the engine while slowly opening the throttle. As an advanced technique for some engines, you can ‘pump’ the throttle in and out a bit to introduce additional fuel from the accelerator boost pump – be careful using this technique and only do it if taught by a qualified instructor, as it can lead to flooding the engine or even causing an engine fire on start up.

Using this technique, the engine will fire when the fuel/air ratio is correct without cranking for long periods – which can overheat starter motors and drain batteries.

If the aircraft engine is primed too much, the engine won’t fire until the throttle is opened wider because the mixture is too rich, (flooding the engine) meaning you need more airflow to match the fuel level, or to help remove excess fuel. The rectification for this is to clear the manifold of fuel by selecting the mixture to idle cut off, turning the fuel pump off, and to crank for a short cycle (5 to 10 seconds) to blow air through the system. Be sure to adhere to any start cycle duty limits so you don’t burn it out. Now you wait for 10 minutes or so for residual fuel to evaporate before starting the engine start sequence again.

If you take too long after priming to crank the engine, the fuel may evaporate or drain away, which means that even with the throttle closed, the air/fuel ratio is too lean to support combustion. This can be dangerous as if you have overprimed and fuel is trickling through the aircraft, it can catch fire when the aircraft starts. Always stick to the pilots operating handbook and don’t overprime!

“Your engine starts by getting the right components spinning while adding fuel and a spark. Knowing these basics doesn’t just help you on your next flight review or checkride, they can be important for improving the lifespan and health of the engine.”

Nicolas Shelton – boldmethod.com5

Throttle position for engine start4

The ideal start occurs when the engine starts to fire at idle or just above because it’s easiest on the engine, doesn’t waste fuel, reduces cranking time, and doesn’t wash oil off the cylinder walls as excess fuel drains. Starting an engine with wide open throttle can be dangerous and is hard on the engine as it hasn’t had time to warm up or distribute fresh lubricating oil to all components (which is why we always aim to reduce RPM below 1000 until the oil pressure and temperature rises).

It can also be extremely dangerous starting at wide open throttle positions due to controllability – many accidents sadly have occurred on start up due to open throttles. Aircraft can jump chocks and parking brakes could flick off (or fail) and the aircraft can move forward, or it could produce dangerous prop wash (damaging other aircraft), or for high-performance aircraft, you might even experience controllability issues due to P-factor and propwash wanting to yaw and roll the aircraft over.

Summary

Starting piston engines5 can be tricky, but after some practice and familiarisation with your aircraft, as well as following this guide and steps above, you will get the hang of it.

Do you have experience starting a piston engine aircraft, or any other aircraft engines, and would you add any further tips here? Let us know in the comments!

References List:

- ‘Aircraft Piston Engine Operation’, Aero Toolbox, Accessed online at https://aerotoolbox.com/aircraft-engine-operation/ on Sep 15, 2022.

- ‘When to Prime a Piston Aircraft Engine’, Aviation Oil Outlet, Published: May 15, 2018. Accessed online at https://aviationoiloutlet.com/blog/when-to-prime-a-piston-engine/ on Sep 15, 2022.

- ‘The Evolution of Engine Starting; From Hand Propping to Button Pushing, David J Williams, NYC Aviation. Published: March 6, 2015. Accessed online at http://www.nycaviation.com/2015/03/tech-talk-airplanes-start-engines/38357 on Sep 15, 2022.

- ‘Try a Zero Throttle Start’, Dean Showalter, PilotWorkshops.com. Accessed online at https://pilotworkshop.com/tips/zero-throttle-start/ on Sep 15, 2022.

- ‘How Does An Aircraft Engine Start?’, Nicolas Shelton, Boldmethod. Published May 24, 2022. Accessed online at https://www.boldmethod.com/learn-to-fly/systems/how-does-a-plane-start/ on Sep 15, 2022.